Geolam: the composite wood inventor, symbol of 50 years of expertise

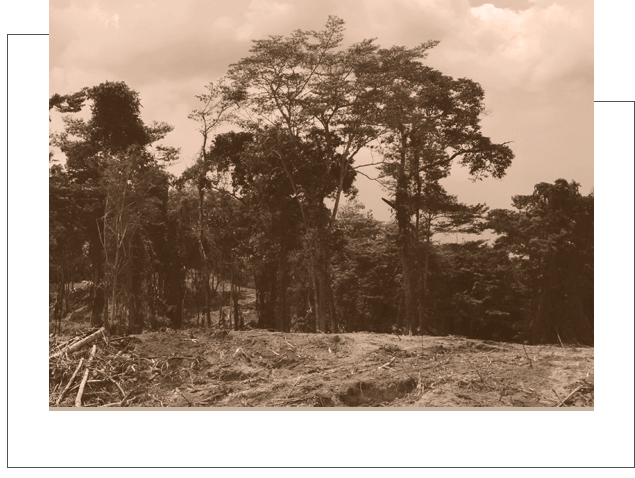

Geolam was built on a sound philosophy. Over 50 years ago, Sadao Nishibori, a dealer in tropical timber from Japan, invented an entirely innovative wood composite. He found his inspiration on a trip through the forests of Indonesia, where he had seen at first hand the consequences of widespread and uncontrolled deforestation. For a cultured, educated and sensitive man, raised in the Shinto tradition with a profound respect for nature, it was a shock. Sadao Nishibori subsequently dedicated himself to the invention of a tropical wood substitute, more respectful of the environment: the wood composite.

The qualities of rare tropical hardwoods served as a standard in developing the Geolam wood composite. He took recycled softwood and recycled polymer resin (polypropylene) to create a material that can now look back on five decades of refinement and whose defining features include a natural wood look coupled with outstanding durability.

1975

Composite wood invented in Japan by Sadao Nishibori, an importer in tropical timber.

1982

First international patent: The world discovers composite wood as the product is commercialized.

1992

Hollow technology for profiles is developed: lighter and stronger, it outclasses solid composite boards.

2002

Honeycomb co-extrusion: a breakthrough that allows you to take advantage of the characteristics of separate materials, but fused into a single blade. Since 2002, our WPC blades have remained at the cutting edge of technology.

2008

Hybrid wood: Hybrid wood products are developed. These exclusive premium boards out-perform all composites developed to date.

2020

Second Generation: After more than a decade of success with hybrid woods, wood-resin blends and extrusion techniques are optimized in line with ever-evolving standards.